Automatic Pet Food Feeders

2022-12-20

Here is a description of the typical R&D process for an automatic pet feeder:

Research and Conceptualization: The R&D team conducts thorough market research to identify the needs and preferences of pet owners. They gather insights on existing pet feeders, their limitations, and areas for improvement. Based on this research, they develop a conceptual framework for the automatic pet feeder.

Design and Prototyping: The team begins the design phase by creating detailed product specifications and mechanical drawings. Using computer-aided design (CAD) software, they generate 3D models of the automatic pet feeder, considering factors like size, capacity, and durability. These designs are then used to create prototypes for testing and validation.

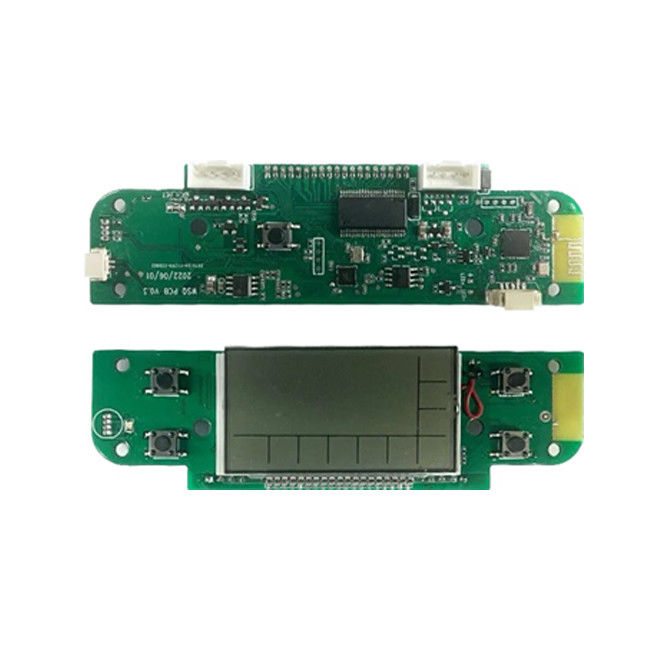

Component Selection and Integration: During this stage, the team carefully selects and sources the necessary components for the automatic pet feeder. These components may include a programmable control system, motorized dispensing mechanism, food storage compartments, sensors, and a user interface. The components are integrated into the prototype, ensuring proper functionality and compatibility.

Testing and Iteration: The prototype undergoes rigorous testing to evaluate its performance, reliability, and user-friendliness. Tests may include dispensing accuracy, motor efficiency, power consumption, ease of programming, and durability. Based on the test results, necessary adjustments and improvements are made to enhance the functionality and address any issues identified during testing.

Software Development: If the automatic pet feeder includes programmable features or connectivity options, the R&D team develops the necessary software. This includes creating user interfaces, programming the control system, and ensuring seamless integration with mobile apps or other smart home systems.

Production Optimization: Once the prototype successfully passes all tests and meets the desired performance standards, the R&D team works on optimizing the production process. They fine-tune manufacturing techniques, optimize material usage, and streamline assembly processes to ensure efficient and cost-effective mass production.

Quality Assurance: Quality control measures are implemented throughout the production process to ensure that each unit of the automatic pet feeder meets the defined standards. This includes testing individual components, conducting assembly line inspections, and performing final product testing before packaging and shipment.

Launch and Market Feedback: The automatic pet feeder is introduced to the market, and customer feedback is gathered. This feedback helps identify areas for further improvement and potential future enhancements. The R&D team takes this feedback into consideration for future iterations or new product developments.

By following these steps, the R&D team can develop an automatic pet feeder that meets the needs of pet owners while ensuring its functionality, durability, and ease of use.